Can a Rack Mount Active Harmonic Filter clean up my power fast without rebuilding the panel?

2025-12-09

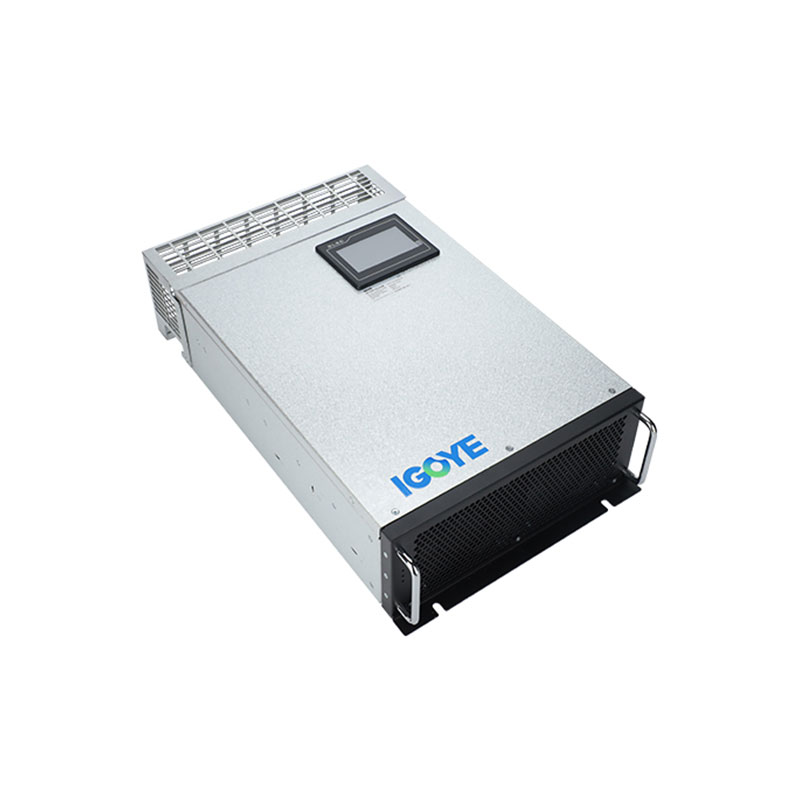

I manage projects where downtime gets priced in minutes, not days. After chasing nuisance trips and inflated energy bills across multiple lines, I kept seeing the same pattern: harmonics from VFDs, welders, and UPS systems chewing through my margins. That’s when I started testing solutions from GEYA and put a Rack Mount Active Harmonic Filter into one of our most cramped panels. What surprised me wasn’t just the drop in THD, but how quickly I could integrate it without a cabinet redesign.

What problems am I actually trying to solve?

- Overheated transformers and cables even when average load looks “normal.”

- Random breaker trips on lines with heavy drive or rectifier use.

- UPS alarms and PLC glitches that mysteriously vanish when non-linear loads are off.

- Bills that don’t match expected kWh because of poor power quality and penalties.

- Failed compliance against internal targets or IEEE 519 guidelines at the PCC.

When these symptoms stack up, a Rack Mount Active Harmonic Filter lets me inject the right compensating current in real time instead of relying on oversizing gear or hoping passive traps hit the right harmonic orders.

How does a rack-mount active approach compare to passive options I’ve tried?

- Tuned versus adaptive — Passive filters are tuned to specific orders; an active unit tracks changing loads and cancels a broad spectrum dynamically.

- Footprint versus flexibility — Panel real estate is precious. A Rack Mount Active Harmonic Filter slots into standard racks or shallow spaces instead of demanding a new cabinet.

- Interaction risks — I’ve seen passive banks “pull” unwanted resonances with cap banks. Active filters avoid that by injecting targeted counter-current.

- Scalability — Need more mitigation later? I can parallel additional rack modules instead of ripping and replacing hardware.

What should I size before I commit?

- Measure where it matters — I verify THD at the problem bus and record drive loading over shifts; nameplate numbers aren’t enough.

- Pick a current rating with headroom — I size the Rack Mount Active Harmonic Filter for typical distortion plus growth, not just today’s average.

- Check harmonic orders — If 5th/7th dominate now but 11th/13th rise during changeovers, I want a device that cancels across orders simultaneously.

- Mind the thermal path — Rack mount helps airflow planning; I still validate ambient and clearances for continuous duty.

- Plan the upstream protection — I coordinate breakers and fuses with the filter’s inrush and fault behavior.

Where does the rack-mount form factor save my weekend?

- Brownfield upgrades — Legacy MCCs with no spare space; a Rack Mount Active Harmonic Filter lets me add mitigation in the same footprint.

- Modular builds — Skid systems and containerized plants benefit from standard rack rails and quick swap units.

- Phased rollout — I can stage filters line by line, proving ROI before scaling.

What quick selection rules of thumb help me start right?

| Typical load | Common symptom | Target THD at bus | Initial filter current pick | Notes |

|---|---|---|---|---|

| VFD clusters (15–75 kW each) | 5th/7th harmonics, cable heat | < 8–10% under normal shifts | 20–40% of total non-linear current | Start with one Rack Mount Active Harmonic Filter, leave space to parallel a second. |

| Welders/rectifiers | Flicker, breaker trips | < 5–8% during peaks | 30–50% of process current | Dynamic response matters; verify millisecond-level tracking. |

| UPS + server racks | Neutral overheating, alerts | < 5% at PDU | 20–30% of IT load | Rack form factor aligns with white-space designs. |

| Mixed process lines | Intermittent alarms | < 8–10% overall | 25–40% of non-linear block | Log across shifts; pick an adaptive Rack Mount Active Harmonic Filter. |

Which installation steps keep me out of trouble?

- Place CTs correctly — Polarity and phasing matter; I verify the reference bus and load orientation to ensure the Rack Mount Active Harmonic Filter injects in the right direction.

- Keep cable runs tight — Short, low-impedance paths reduce stray inductance and improve cancellation accuracy.

- Commission in stages — I start in monitor mode, capture baseline THD, enable compensation gradually, and document before/after.

- Validate thermal profile — I log temps at 15-min intervals under worst-case duty to confirm airflow assumptions.

- Lock in settings — Passwords, event logs, and alarms are mapped to our SCADA or BMS on day one.

How do I prove ROI without a long essay?

- Energy quality KPIs — THD(I/V) at the bus, neutral current, transformer hot-spot temperature.

- Reliability KPIs — Trip frequency, drive fault counts, UPS alerts per week.

- Financial KPIs — Penalty reductions, avoided downtime, deferred cable/transformer upgrades.

- Sustainability KPIs — Lower thermal losses and better utilization of existing capacity.

When those move in the right direction after deploying a Rack Mount Active Harmonic Filter, the business case sells itself.

What practical features do I look for before I sign the PO?

- Wide-band cancellation with fast response across varying loads.

- Parallel scalability so I can add modules as production grows.

- Rack depth and airflow compatible with my existing enclosures.

- Clear diagnostics — onboard trends, alarms, and simple CT checking tools.

- Serviceability — front access, hot-swap fans, and clean cable management.

These are the details that make a Rack Mount Active Harmonic Filter a dependable part of my power quality strategy instead of a science project.

Why am I leaning toward this for upcoming lines?

Because I can drop a Rack Mount Active Harmonic Filter into a crowded panel, cut distortion in hours, and defer bigger capex. In plants where every square inch is spoken for, that flexibility matters as much as the THD number on a report.

Ready to see clean power on your next shift?

If you’re fighting alarms, heat, or penalties, I’m confident a Rack Mount Active Harmonic Filter belongs on your shortlist. Tell me about your loads, share a quick data capture, and let’s translate problems into a plan. If you’re evaluating options from partners like GEYA and want a practical sizing review, contact us to compare approaches, request a quote, or book a short technical walk-through. Your lines don’t need another rebuild — they need cleaner current and a faster path to uptime.