How Do Optic Gyroscopes Enhance Navigation Systems?

2025-10-14

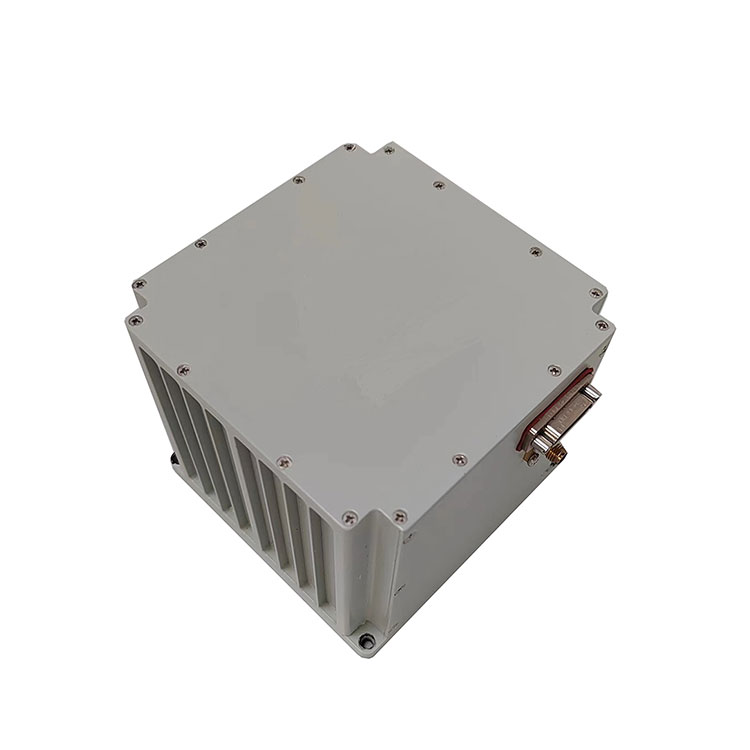

Optic gyroscopes, also known as fiber optic gyroscopes (FOGs), represent a breakthrough in precision navigation technology. Unlike traditional mechanical gyroscopes, optic gyroscopes utilize the interference of light traveling through optical fibers to measure rotational movement with extraordinary accuracy. This technology has become a cornerstone in aerospace, maritime, defense, and industrial applications, where precise navigation and orientation are critical. The purpose of this article is to explore the functionality, advantages, and future trends of optic gyroscopes, providing an in-depth guide for engineers, researchers, and decision-makers seeking state-of-the-art navigation solutions.

How Do Optic Gyroscopes Work?

Optic gyroscopes operate based on the Sagnac effect, which occurs when two beams of light travel in opposite directions around a fiber optic coil. The phase difference created by rotational motion allows the device to calculate angular velocity accurately. Unlike mechanical gyroscopes, optic gyroscopes have no moving parts, making them highly reliable and resistant to mechanical wear and vibration.

Key technical parameters of a typical optic gyroscope can be summarized as follows:

| Parameter | Specification |

|---|---|

| Measurement Range | ±300°/s to ±2000°/s |

| Bias Stability | <0.01°/h |

| Scale Factor Stability | ±50 ppm |

| Angular Random Walk (ARW) | 0.001°/√h |

| Operating Temperature | -40°C to +85°C |

| Power Consumption | 5–15 W |

| Dimensions | 150 mm × 100 mm × 50 mm |

| Weight | 1.2–1.5 kg |

| Output Interface | RS422 / Ethernet / CAN |

| Lifetime | >20 years |

The high accuracy, minimal maintenance, and compact design make optic gyroscopes suitable for both airborne and ground-based navigation systems.

Why Are Optic Gyroscopes Preferred Over Mechanical Gyroscopes?

The adoption of optic gyroscopes is driven by their numerous advantages:

-

Durability and Reliability: No moving parts reduce the risk of mechanical failure.

-

High Precision: Fiber optic gyroscopes can detect angular changes with an accuracy of fractions of a degree per hour.

-

Environmental Resistance: Stable performance under extreme temperatures, vibrations, and shocks.

-

Compact and Lightweight: Ideal for aerospace and unmanned systems where space and weight are critical.

-

Low Maintenance: Reduced mechanical complexity leads to longer operational life and lower maintenance costs.

These advantages make optic gyroscopes indispensable in modern navigation applications, particularly where GPS signals may be weak or unavailable.

What Are the Key Applications and Future Trends of Optic Gyroscopes?

Optic gyroscopes are widely employed in aerospace, maritime, defense, and industrial sectors. Some specific applications include:

-

Aircraft Navigation: Providing precise attitude, heading, and yaw measurements.

-

Submarine and Naval Systems: Enabling underwater navigation where GPS is unavailable.

-

Autonomous Vehicles: Supporting advanced driver-assistance systems (ADAS) and self-driving cars.

-

Robotics and Industrial Automation: Ensuring accurate orientation and motion control.

-

Spacecraft and Satellites: Maintaining orientation in orbit for communications and observation systems.

Future Trends

The future of optic gyroscopes is shaped by continuous innovation in optical technology and miniaturization:

-

Integration with MEMS Technology: Combining micro-electromechanical systems with fiber optics for compact, high-precision solutions.

-

Enhanced Signal Processing: Improved algorithms reduce noise and enhance long-term stability.

-

Mass Production for Commercial Vehicles: Lower costs will expand use in automotive and unmanned systems.

-

Hybrid Navigation Systems: Integrating optic gyroscopes with GPS, accelerometers, and magnetometers for superior redundancy and reliability.

These trends indicate that optic gyroscopes will not only remain critical in defense and aerospace but will also become mainstream in civilian navigation and autonomous systems.

How to Choose the Right Optic Gyroscope for Your Application?

Selecting an appropriate optic gyroscope requires careful consideration of several factors:

-

Measurement Accuracy: Match bias stability and angular random walk to your application requirements.

-

Environmental Tolerance: Ensure the device can operate in expected temperature, vibration, and shock conditions.

-

Size and Weight Constraints: Critical for aerospace, UAVs, and mobile platforms.

-

Interface Compatibility: Confirm communication protocols match existing systems.

-

Lifecycle and Maintenance: Consider operational lifespan and ease of maintenance to optimize long-term costs.

Common Questions About Optic Gyroscopes

Q1: How does an optic gyroscope maintain accuracy without GPS?

A1: Optic gyroscopes rely on the Sagnac effect to measure angular velocity independently of external signals. This enables accurate dead-reckoning navigation even in GPS-denied environments. Advanced signal processing minimizes drift, ensuring reliability over extended periods.

Q2: What maintenance is required for optic gyroscopes?

A2: Unlike mechanical gyroscopes, fiber optic gyroscopes have no moving parts, which dramatically reduces maintenance needs. Periodic calibration and environmental inspections are recommended to maintain peak performance, but the device can typically operate for decades without significant intervention.

Conclusion

Optic gyroscopes represent a pinnacle of navigation technology, offering unmatched precision, reliability, and versatility. Their adoption across aerospace, defense, autonomous vehicles, and industrial automation highlights their importance in modern engineering solutions. By integrating advanced optical and signal-processing techniques, these gyroscopes are set to define the future of navigation systems.

JioptiK continues to innovate in the field of optic gyroscopes, delivering high-performance solutions tailored to complex operational needs. For tailored solutions and technical consultations, contact us to explore how JioptiK can enhance your navigation and orientation systems.