How Does a Pipe Temperature Controller Work and Why is it Important?

2025-12-18

Abstract: Pipe Temperature Controllers are critical components in industrial and commercial systems where precise thermal management is required. This guide explores their working principles, specifications, applications, and common questions, providing a comprehensive resource for engineers, technicians, and decision-makers.

Table of Contents

1. Introduction to Pipe Temperature Controllers

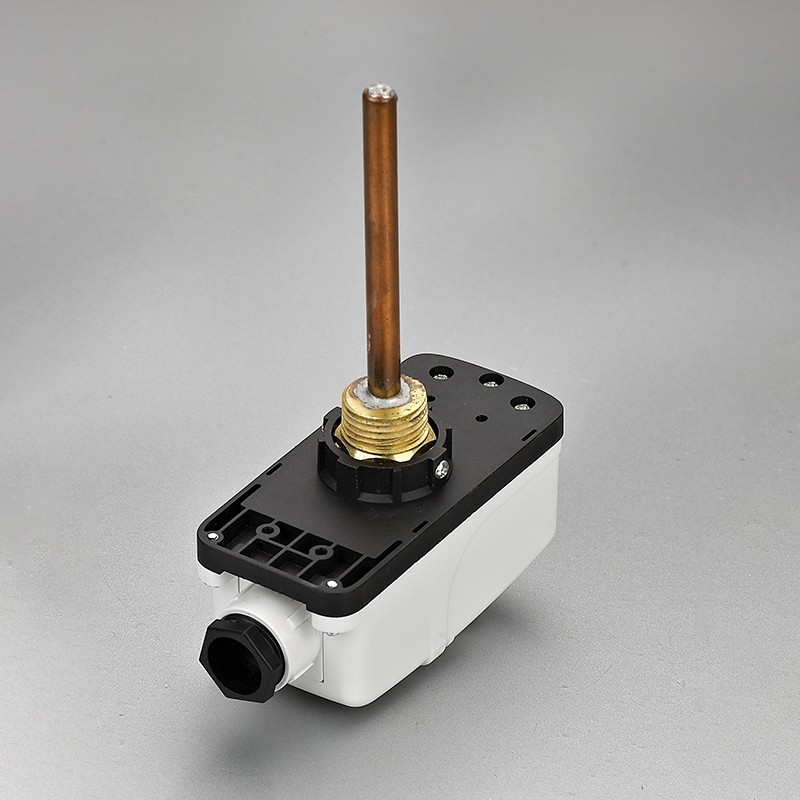

Pipe Temperature Controllers are advanced devices designed to regulate and maintain precise temperatures in fluid transport systems. They are widely used in industries such as chemical processing, food and beverage production, pharmaceuticals, and HVAC systems. These controllers ensure thermal stability, energy efficiency, and equipment protection by monitoring temperature in real time and adjusting heating or cooling mechanisms accordingly.

The main focus of this article is to provide an in-depth understanding of how Pipe Temperature Controllers function, their technical parameters, practical applications, and answers to the most frequently asked questions, allowing users to select and operate them effectively.

2. Key Specifications

Pipe Temperature Controllers come with a range of specifications depending on the application requirements. The most critical parameters include temperature range, control accuracy, sensor type, power rating, and response time. Below is a representative specification table for a standard industrial-grade controller:

| Parameter | Specification |

|---|---|

| Temperature Range | -50°C to 250°C |

| Control Accuracy | ±1°C |

| Sensor Type | PT100 / Thermocouple |

| Power Supply | AC 220V / 50Hz |

| Output Type | SSR / Relay |

| Response Time | ≤2 seconds |

| Mounting Type | Wall-mounted / DIN Rail |

3. Industrial and Commercial Applications

Pipe Temperature Controllers are essential in processes where precise thermal management is required. They are commonly used in:

- Chemical Processing: Maintaining consistent reaction temperatures to ensure product quality.

- Food and Beverage Industry: Controlling pasteurization, heating, and cooling of liquids.

- Pharmaceutical Manufacturing: Ensuring accurate thermal conditions during formulation and storage.

- HVAC Systems: Regulating water or coolant temperatures in heating and cooling circuits.

- Plastic Extrusion and Injection Molding: Preventing material degradation by controlling barrel temperatures.

The proper selection and installation of a Pipe Temperature Controller can significantly improve operational efficiency, reduce energy consumption, and extend the service life of industrial equipment.

4. Frequently Asked Questions about Pipe Temperature Controllers

Q1: How does a Pipe Temperature Controller measure the temperature?

A1: Pipe Temperature Controllers use sensors such as PT100 or thermocouples that are attached to the pipe surface or immersed in the fluid. These sensors detect temperature changes and convert them into electrical signals, which the controller interprets to adjust heating or cooling outputs.

Q2: How can one ensure accurate temperature control with a Pipe Temperature Controller?

A2: Accuracy is ensured by selecting the correct sensor type, calibrating the controller regularly, and minimizing external thermal interference. Proper installation, including insulation of pipes and positioning of sensors, is critical for consistent control.

Q3: How to troubleshoot common issues with Pipe Temperature Controllers?

A3: Common troubleshooting steps include checking power supply stability, ensuring sensor integrity, inspecting wiring and connections, and verifying controller settings. Regular maintenance and firmware updates (if digital) also prevent operational issues.

5. Brand and Contact Information

Zhejiang Huaxi Electronics Co., Ltd. specializes in manufacturing high-precision Pipe Temperature Controllers suitable for a wide range of industrial applications. Their products are known for reliability, fast response, and durable design.

For further inquiries, product specifications, or bulk purchasing options, contact us directly to speak with a technical representative who can provide personalized recommendations based on your specific requirements.