How Does a SAE NPTF Hydraulic Adapter Improve Hydraulic System Performance?

2026-01-09

Article Summary: This article explores the essential role of SAE NPTF hydraulic adapters in modern hydraulic systems. It covers types, material selection, installation techniques, common challenges, and practical maintenance tips. The guide aims to help engineers, technicians, and procurement specialists select and use SAE NPTF adapters efficiently while minimizing leaks and downtime.

Table of Contents

- Introduction

- What is SAE NPTF Hydraulic Adapter?

- Types and Specifications

- Installation Tips

- Common Issues and Solutions

- Material Selection and Durability

- Maintenance Guide

- Frequently Asked Questions

- Conclusion

Introduction

Hydraulic systems rely on precision fittings to ensure reliable operation under high pressure. SAE NPTF hydraulic adapters offer a specialized solution for leak-free connections, particularly in applications requiring high integrity and performance. Choosing the right adapter, understanding its specifications, and following proper installation practices are critical for maintaining system efficiency.

What is SAE NPTF Hydraulic Adapter?

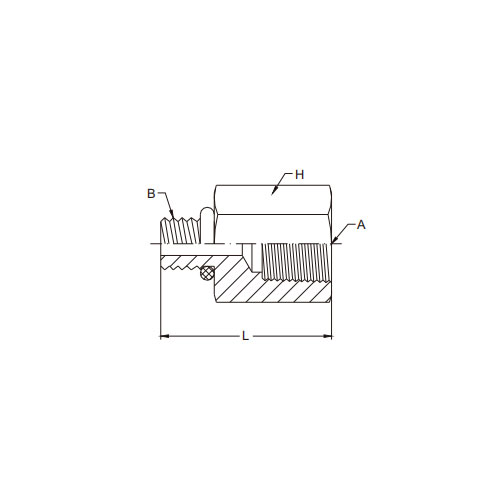

SAE NPTF (National Pipe Taper Fuel) hydraulic adapters are designed to create a mechanical seal without the need for additional sealing compounds. Unlike standard NPT threads, NPTF threads are manufactured to tighter tolerances, which allows threads to deform slightly under torque, providing a leak-free metal-to-metal connection.

- Applications: Mobile hydraulics, industrial machinery, construction equipment, and fluid transfer systems.

- Key Feature: High-pressure resistance and leak prevention without sealants.

- Compatibility: Works with SAE straight thread and tapered ports in hydraulic systems.

Types and Specifications

SAE NPTF adapters come in various configurations to accommodate different system designs. Below is a summary of commonly used types:

| Type | Description | Typical Use |

|---|---|---|

| Male to Female | Connects male and female NPTF threaded components | General hydraulic system connections |

| Male to Male | Joins two female ports | Pipeline extensions |

| Elbow (90°) | Changes flow direction without stress on hoses | Tight installation spaces |

| Reducer | Connects different thread sizes | Custom hydraulic layouts |

| Adapter with O-Ring | Provides additional sealing for high-pressure applications | High-performance hydraulic circuits |

Installation Tips

Proper installation ensures the adapter’s leak-free performance and longevity. Consider the following tips:

- Always clean threads before installation to avoid debris interference.

- Use appropriate torque specifications; overtightening may deform threads and under-tightening may cause leaks.

- Apply thread sealant only if specified for the application, though NPTF threads typically do not require it.

- Inspect mating ports to ensure compatibility with SAE NPTF standards.

Common Issues and Solutions

Even high-quality SAE NPTF adapters may encounter challenges if not handled correctly. Common problems include:

- Leakage: Often caused by cross-threading or improper torque. Solution: re-torque or replace damaged adapters.

- Thread Galling: Metal-to-metal contact may lead to thread wear. Solution: use anti-seize compound during assembly.

- Misalignment: Incorrect installation angle can stress hydraulic hoses. Solution: choose appropriate elbow or swivel adapters.

Material Selection and Durability

Material choice affects the performance and longevity of SAE NPTF adapters:

- Carbon Steel: Strong and cost-effective, suitable for general hydraulic applications.

- Stainless Steel: Corrosion-resistant, ideal for marine or chemical hydraulic systems.

- Brass: Lightweight, suitable for low-pressure hydraulic circuits.

Surface treatments like zinc plating or passivation enhance corrosion resistance and extend service life.

Maintenance Guide

Regular inspection and maintenance reduce unexpected downtime and improve system reliability:

- Check adapters periodically for signs of wear or corrosion.

- Inspect connections after each maintenance cycle or hydraulic system modification.

- Replace adapters that show thread damage or leakage.

- Keep spare adapters available to minimize system downtime.

Frequently Asked Questions

-

Q1: Can SAE NPTF adapters be used with standard NPT ports?

Yes, but they may not provide a perfect seal since standard NPT threads are not as tight. -

Q2: What is the maximum pressure rating for SAE NPTF adapters?

Pressure rating varies by size and material, but typical ratings range from 3,000 to 6,000 PSI. -

Q3: Do SAE NPTF adapters require thread sealant?

Generally, no. Their precision threads are designed to seal without additional compounds. -

Q4: How to prevent thread galling?

Use anti-seize compound and avoid overtightening during installation.

Conclusion

SAE NPTF hydraulic adapters are critical components for ensuring leak-free, high-pressure hydraulic connections. Selecting the correct type, using proper installation techniques, and performing regular maintenance can significantly improve system performance. For reliable sourcing and technical support, Ningbo WayFong Hydraulic Machinery Co., Ltd. provides a wide range of SAE NPTF adapters with superior quality and timely delivery. To learn more or place an order, contact us today.