How to Choose and Use Solar Panel Cable for Efficient Solar Energy Systems?

2025-12-26

Abstract: This article provides a comprehensive guide to Solar Panel Cable, including key parameters, installation considerations, and answers to frequently asked questions. It aims to help professionals and solar enthusiasts make informed choices for high-performance solar power systems.

Introduction

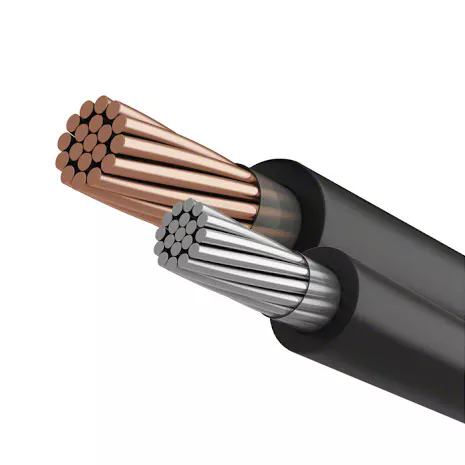

Solar Panel Cable is a specialized electrical cable designed for photovoltaic (PV) systems, ensuring safe and efficient transmission of electricity generated by solar panels. It must withstand environmental challenges such as UV radiation, high temperatures, and moisture. This article focuses on selecting, installing, and understanding Solar Panel Cable, detailing technical parameters, best practices, and frequently asked questions for comprehensive guidance.

Solar Panel Cable Parameters

The performance and durability of Solar Panel Cable are influenced by several technical specifications. Below is a detailed table summarizing standard professional-grade parameters:

| Parameter | Specification |

|---|---|

| Conductor Material | High-purity Copper or Tinned Copper |

| Cross-sectional Area | 2.5mm² – 16mm² |

| Voltage Rating | 600V – 1500V DC |

| Temperature Range | -40°C to +120°C |

| UV Resistance | IEC 61215 & IEC 61730 compliant |

| Insulation Material | XLPE / PV1-F / TUV certified |

| Jacket Color | Black / Red / Blue |

| Standards | IEC 62852, UL 4703, RoHS Compliant |

Installation and Safety Guidelines

Correct installation is crucial for long-term performance and safety of Solar Panel Cable. Key considerations include:

1. Cable Routing

Ensure cables are routed away from sharp edges, high-traffic areas, and potential sources of mechanical damage. Properly securing cables with clamps or conduits reduces wear and tear.

2. Connection and Termination

Use MC4 or compatible connectors for all terminations. Ensure connections are tight, corrosion-resistant, and weatherproof. Avoid over-bending or twisting cables, which may compromise insulation integrity.

3. Environmental Considerations

Solar Panel Cable must resist UV exposure, moisture, and extreme temperatures. Install cables in ventilated, shaded, or protected areas whenever possible. Avoid direct contact with chemicals or abrasive surfaces.

4. Testing and Maintenance

Regularly inspect for cracks, discoloration, or loose connections. Measure voltage drop and continuity to ensure optimal performance. Replace damaged cables immediately to prevent fire hazards or system inefficiencies.

Common Questions About Solar Panel Cable

Q1: What is the difference between standard electrical cables and Solar Panel Cable?

A1: Standard electrical cables are designed for general power distribution, whereas Solar Panel Cable is specifically engineered for photovoltaic systems. It features higher UV resistance, enhanced thermal tolerance, and compliance with solar-specific standards like IEC 62852, ensuring long-term outdoor durability.

Q2: How do I determine the correct size of Solar Panel Cable for my system?

A2: Cable size depends on current rating, system voltage, and distance between panels and inverters. Oversized cables reduce voltage drop but increase cost. Use voltage drop calculators or consult IEC/UL guidelines to select appropriate cross-sectional area for efficiency and safety.

Q3: Can Solar Panel Cable be buried underground?

A3: Certain solar cables are rated for direct burial, typically with additional protective jackets. Verify the cable meets local standards for underground installation, and ensure proper trenching, conduit usage, and moisture protection to maintain performance and longevity.

Conclusion

Understanding Solar Panel Cable is essential for the design and maintenance of efficient solar energy systems. Proper selection, installation, and routine inspection ensure system longevity and safety. For high-quality professional-grade cables, DAYA electrical offers a wide range of reliable solutions for residential, commercial, and industrial solar projects. Contact us to explore customized options and technical support for your solar power system needs.