Is a Wall-mounted Static Var Generator the Smart Fix for Tight Spaces and Unstable Power Quality?

2025-12-16

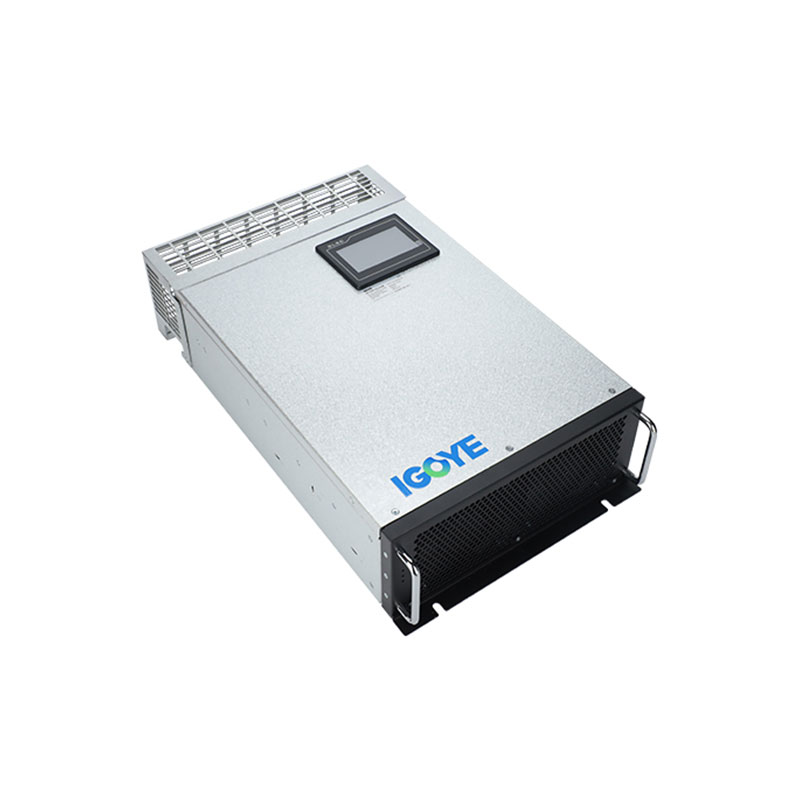

I started looking for a compact way to stabilize voltage, improve power factor, and reduce penalties without sacrificing floor space. That search is how I ran into Geya and their approach to a Wall-mounted Static Var Generator that fits where a traditional cabinet simply can’t. If you’re dealing with tight electrical rooms, frequent load swings, or picky utility requirements, you’ll recognize the headaches I’m about to unpack.

Why do so many sites struggle with voltage dips and power factor issues even after adding capacitors?

In my experience, conventional capacitor banks can help on paper, but they often fall short when the load is dynamic. Motors starting and stopping, welders, compressors, elevators, and fast-changing inverter loads can cause:

- Voltage flicker that annoys production lines and sensitive electronics

- Power factor drifting throughout the day

- Overcompensation at light load and undercompensation at peak load

- Switching transients and maintenance overhead

That’s why I treat a Wall-mounted Static Var Generator as a “dynamic” tool rather than a static add-on. The goal is fast reactive power support that follows the load, instead of guessing a fixed step value.

What exactly should I expect a Wall-mounted Static Var Generator to solve on a busy electrical bus?

When I evaluate a Wall-mounted Static Var Generator, I focus on measurable outcomes that matter to operations and compliance:

- Power factor correction to reduce utility penalties and transformer stress

- Voltage stabilization to cut nuisance trips and improve process consistency

- Fast response to load changes where step capacitors feel “too slow” or “too coarse”

- Better compatibility with modern loads such as VFDs, servo drives, and automation equipment

- Space-saving installation for retrofit projects that can’t expand floor cabinets

The “wall-mounted” part isn’t a gimmick. In retrofit work, space is often the real constraint, not the budget.

How does a wall-mounted design change installation and commissioning realities?

I’ve learned the hard way that the best-performing solution is worthless if it slows down site work. A wall-mounted format usually helps because:

- It can be positioned closer to the point of compensation, reducing wiring complexity

- It keeps walkways and service areas clear compared with full floor-standing cabinets

- It can simplify retrofit schedules when shutdown windows are short

For a Wall-mounted Static Var Generator, I always plan commissioning around the actual load behavior. If the load is highly intermittent, I make sure settings and control targets reflect that reality instead of an “average day” that never happens.

What pain points make buyers regret picking the cheapest reactive power solution?

If you only compare upfront price, you may miss the costs that show up later. The most common regrets I see:

- Frequent capacitor replacement due to heat, harmonics, or harsh switching duty

- Unstable power factor because the load profile is variable, not steady

- Voltage complaints that persist even after “correction” equipment is installed

- Downtime and troubleshooting because the system can’t adapt fast enough

That’s why I usually frame the conversation around lifecycle value. A Wall-mounted Static Var Generator can be an operational tool, not just a compliance band-aid.

Which technical features should I compare when evaluating options?

Here’s the feature checklist I use when I’m comparing different models and suppliers, including Geya:

- Reactive power capacity range that matches your worst-case load swings

- Response speed that keeps up with real events like motor starts and load steps

- Control target options such as power factor setpoint, voltage setpoint, or mixed modes

- Thermal design for continuous operation in warm electrical rooms

- Protection and alarms to prevent silent failures and hidden performance loss

- Ease of maintenance including access, diagnostics, and clear indicators

How do I decide whether a Wall-mounted Static Var Generator is the right fit versus capacitor banks or other solutions?

I like to map solutions to site conditions rather than chasing a one-size-fits-all answer. This comparison table is how I explain it internally.

| What I am trying to fix | Step Capacitor Banks | Wall-mounted Static Var Generator | Common result if chosen poorly |

|---|---|---|---|

| Fast load swings and frequent motor starts | Often too slow or too coarse | Designed to track changes quickly | Voltage flicker and unstable power factor |

| Limited floor space in electrical room | Cabinet footprint may be an issue | Wall-mounted form helps free up space | Project delays or compromised layout |

| Penalties from poor power factor | Can help if load is steady | Works better when load is variable | Penalty reduction less than expected |

| Process sensitivity to voltage fluctuations | May not stabilize quickly enough | Targeted dynamic support is possible | Nuisance trips and unstable production |

| Long-term maintenance and uptime | Wear items may need more frequent attention | Focus on monitoring and controlled operation | Hidden performance loss over time |

What questions should I ask before sizing and ordering?

Before I sign off on a Wall-mounted Static Var Generator, I ask for the data that prevents surprises:

- What is the maximum and minimum load, and how quickly does it change?

- What is the current power factor profile across a full week, not just a single day?

- Are there harmonics from VFDs, UPS systems, or rectifiers that affect compensation behavior?

- Where is the best installation point to support the most problematic bus or feeder?

- What are the success metrics, such as power factor target, voltage tolerance, or penalty reduction?

How do I explain the business value to a non-technical buyer?

When I pitch this internally, I avoid buzzwords and stick to outcomes:

- Lower utility penalties through consistent power factor

- Fewer trips and fewer “mystery faults” caused by voltage instability

- More stable production quality when sensitive equipment is involved

- Space-efficient retrofit compared with expanding switchroom footprints

If you need a concise way to describe it, I say a Wall-mounted Static Var Generator is a compact, dynamic reactive power tool that helps keep the electrical system calm even when the load is chaotic.

Where should I start if I want to shortlist a supplier quickly?

If you’re shortlisting vendors, I’d start with suppliers who can discuss your load behavior and not just quote a nameplate rating. That’s one reason I kept Geya on my list when I looked into wall-mounted options.

- Ask for application guidance based on your industry and load types

- Request a sizing approach that aligns with your utility rules and site constraints

- Confirm installation and service expectations for your environment

Ready to stabilize your power without sacrificing floor space?

If you’re dealing with voltage swings, power factor penalties, or tight installation space, a Wall-mounted Static Var Generator may be the cleanest path forward. Tell me your load profile, transformer capacity, and current power factor range, and I’ll help you turn that into a practical selection checklist.

Want pricing, configuration guidance, or a quick feasibility check from Geya? Contact us and send your site details so you can get a recommendation that actually matches your operating conditions.