What Is an Earthing Switch and Why Does SanGao Care So Much?

2025-10-13

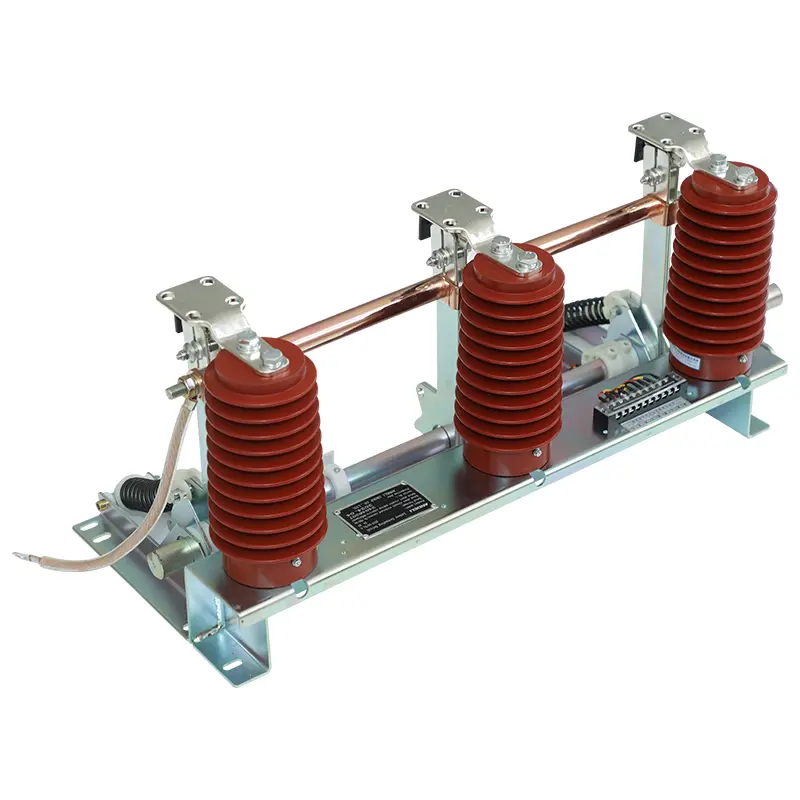

When I joined SanGao two decades ago, we set out with one mission: to make electrical systems safer, especially during maintenance or fault conditions. An Earthing Switch (also called grounding switch) is one of the most critical safety components in power systems. Our brand, SanGao, has refined its designs over years of field operation and customer feedback to deliver dependable, high-performance solutions.

An earthing switch is the device that ensures residual voltage or stray charge is reliably discharged to ground before human intervention. In other words, it protects maintenance personnel, prevents accidental energization, and ensures equipment safety.

In this article, I will walk you through common challenges, how SanGao’s designs address them, and the product parameters you need to evaluate.

What Safety Challenges Do Customers Face When They Use Earthing Switches?

From years of working with utilities, switchgear manufacturers, and industrial clients, I see several recurring pain points:

-

Unreliable closure under short-circuit conditions

-

Slow response or “sticky” mechanical movement

-

Poor interlock logic leading to unsafe operations

-

Difficulty in retrofitting into existing switchgear

-

Lack of clarity in specifications, causing mismatches in site application

By framing the discussion around those, we make sure readers focus on what really matters.

How Does SanGao Design Its Earthing Switch to Overcome Those Challenges?

Here is how we approach designing a robust solution:

-

Snap-action / spring assist mechanism

We ensure the final closing travel is assisted by a spring, delivering consistent and rapid contact even under slight misalignment. -

Mechanical interlocks and sequencing logic

Our designs prevent the earthing switch from closing unless upstream disconnectors or breakers are open, and vice versa. -

High short-circuit making capacity

We dimension contact materials and linkages to sustain transient fault currents during closure without welding or damage. -

Modular and retrofit-friendly form factor

We provide compact mounting options, adapter kits, and flexibility in control (manual, motorized, or pneumatic) to suit existing panels. -

Clear, rich specification datasheets

We supply full parameter tables, performance curves, and factory test reports to support customer selection and verification.

What Are the Key Technical Parameters You Must Know?

Below is a typical specification table for a SanGao earthing switch model series (for medium voltage use). These are representative values—we will customize as per your system conditions.

| Parameter | Typical Value / Range | Purpose / Note |

|---|---|---|

| Rated voltage (Ur) | 12 kV / 24 kV / 36 kV (other levels on request) | Must match system phase-to-ground voltage |

| Lightning impulse withstand voltage (Up) | 75 kV / 95 kV / 125 kV | To resist surge events |

| Rated continuous current (Ir) | 630 A / 1250 A / 2000 A | Current carried under normal (though rarely used) conditions |

| Short-time withstand current (Ik) | 20 kA / 31.5 kA | Ability to survive fault currents for the rated duration |

| Rated short-circuit duration (tk) | 1 s / 2 s | Duration over which the device endures Ik |

| Operating angle | 90° to 120° | Movement travel of switch blade search.abb.com+1 |

| Operating torque | (varies by model) | To size actuators or manual effort |

| Control modes | Manual, motorized, spring assisted, pneumatic | Flexibility for different switchgear conditions |

| Interlocking capability | Integrated mechanical and/or electrical interlock | Prevent unsafe sequencing |

| Lifetime mechanical operations | ≥ 10,000 cycles | To ensure durability |

| Ambient temperature range | – 20 °C to + 50 °C (or extended) | For outdoor and indoor application |

| Enclosure protection | IP54 / IP65 / weatherproof options | To resist dust, humidity, etc. |

If you like, I can send the full datasheet PDF for your system class (e.g. 24 kV, 31.5 kA).

Which Standards and Tests Should You Demand?

For a quality earthing switch, here are the standards and tests you should insist on:

-

Type tests per IEC 62271-102 and IEC 62271-1 (for disconnectors/earth switches) EEP - Electrical Engineering Portal+2CHYF Electric+2

-

Short-circuit current tests (making and withstand)

-

Mechanical endurance / cycle tests

-

Temperature rise tests at rated current

-

Mechanical shock, vibration, and environmental aging

-

Interlock functional verification

-

Factory routine tests and report for each delivered unit

At SanGao, before shipping each unit we perform a complete test run to validate contact resistance, movement timings, torque curves, and interlock logic.

How Do SanGao Devices Behave in Different Use Cases?

Let me share three illustrative use scenarios:

-

Substation bus isolator grounding

After opening the bus isolator for maintenance, our earthing switch closes to ground the busbar section. Reliable interlock ensures you cannot accidentally energize while it’s grounded. -

Ring main unit (RMU) integration

In compact RMUs, we offer embedded earthing switches that share actuation mechanism with the isolator, with internal interlocks safeguarding the sequence. -

High-speed grounding for arc fault protection

In more advanced systems, an ultra-fast earthing switch (similar to ABB UFES) can actively trigger 3-phase short to ground during arc faults, extinguishing arcs in just a few milliseconds nepsi.com. SanGao is evolving toward offering that class too.

What Questions Should You Ask When Evaluating an Earthing Switch Supplier?

From my experience, here is a checklist:

-

Can you supply full type test reports per IEC 62271-102?

-

What is your making / closing capacity (peak current) rating?

-

How do you guarantee contact surface quality over lifetime?

-

Do you support retrofit kits for existing switchgear?

-

What is your interlocking logic and how customizable is it?

-

Do you offer motorization or automation options?

-

What quality assurance and warranty do you deliver?

-

Can you share references or site installations in similar systems?

If your supplier can’t answer confidently, you risk unstable performance or early failure.

Why Does SanGao Believe in Our Earthing Switch Solutions?

I’ve spent years reviewing field returns, client feedback, and service logs. Here’s why I believe in what we build:

-

Our spring-assist snap closure design minimizes “partial contact” risk

-

We use contact materials that resist welding under transient faults

-

Our interlock mechanisms (mechanical + electrical) ensure safe sequencing

-

We provide full transparency on test reports and visit support

-

We continuously refine designs based on field data and failure modes

In short, we build for longevity and trust, not just for sale.

What Should You Do Next If You Need a Reliable Earthing Switch?

I hope this article helps clarify what to look for and what questions to ask. If you’re planning a new switchgear project, retrofit, or evaluation, I encourage you to reach out to us. At SanGao, we are ready to share detailed datasheets, system match proposals, and free consultation.

Please contact us today to tell us about your system parameters (voltage, fault current, layout) and I or our engineering team will prepare a personalized solution. We look forward to solving your safety grounding challenges together.