What Makes an AC Contactor Essential for Modern Electrical Systems?

2026-01-06

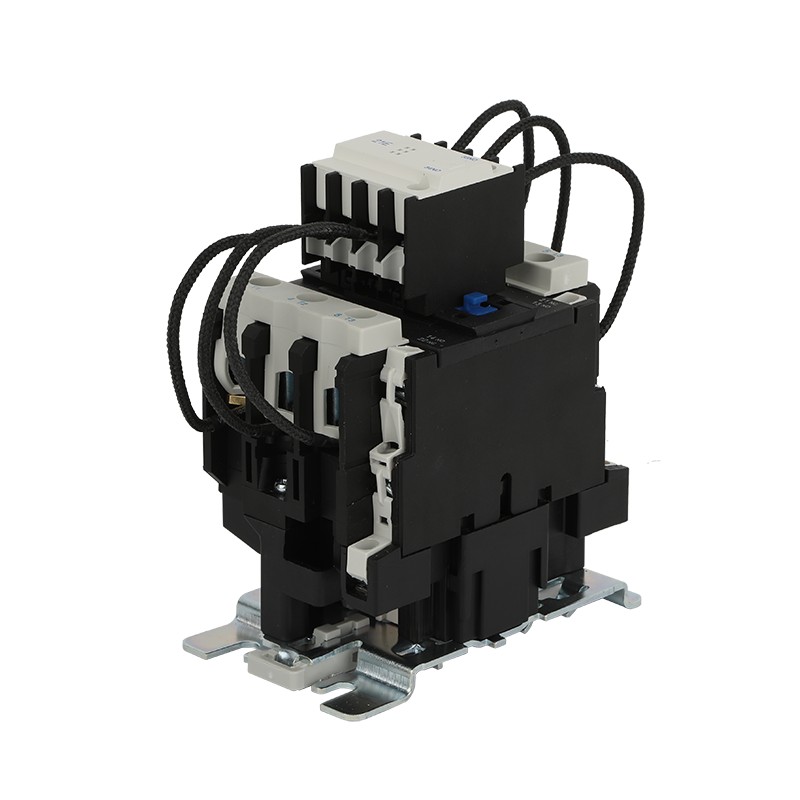

In today's industrial and commercial electrical applications, ensuring efficient and safe control of high-power circuits is paramount. An AC Contactor serves as the cornerstone in controlling alternating current (AC) loads, offering both reliability and automation in electrical systems. Companies like Zhejiang Geyue Electric Technology Co., Ltd. specialize in producing high-quality AC contactors designed to meet diverse operational requirements.

Understanding the AC Contactor

An AC contactor is an electrically-controlled switch used for switching an electrical power circuit. Similar in function to a relay but designed for higher current ratings, it can control motors, lighting systems, heating equipment, and other high-power devices.

Key Features of AC Contactors:

| Feature | Description |

|---|---|

| Rated Voltage | AC 24V – 690V |

| Rated Current | 9A – 800A |

| Pole Numbers | 1P, 2P, 3P, 4P |

| Coil Type | AC Coil or DC Coil |

| Lifespan | Up to 1 million operations |

Why Choose an AC Contactor?

The importance of an AC Contactor lies in its ability to safely manage electrical loads while providing automation and protection. By enabling remote control, it reduces the need for manual switching and minimizes risks associated with electrical accidents. AC contactors are critical in motor starters, HVAC systems, and industrial machinery.

Key Advantages:

-

Reliable Switching: Supports frequent operation without overheating.

-

High Load Capacity: Handles large currents effortlessly.

-

Safety: Protects circuits from overloads and short circuits.

-

Automation Friendly: Compatible with smart control systems.

How Does an AC Contactor Work?

AC contactors operate by energizing a coil that generates a magnetic field, which pulls contacts together, allowing current to flow through the main circuit. When the coil is de-energized, the contacts open, interrupting the current. This simple yet robust mechanism ensures consistent performance even under demanding conditions.

Working Cycle of an AC Contactor:

-

Coil Energized → Magnetic field forms

-

Contacts Close → Current flows to the load

-

Coil De-energized → Contacts Open → Current stops

AC Contactor vs. Electromechanical Relay

When selecting devices for industrial electrical control, one common question is: AC Contactor vs. Electromechanical Relay – which is better?

| Feature | AC Contactor | Electromechanical Relay |

|---|---|---|

| Current Capacity | High (up to 800A) | Low (usually <20A) |

| Durability | Long-lasting | Moderate lifespan |

| Application | Motors, HVAC, Industrial Loads | Small circuits, signal switching |

| Cost | Moderate | Low |

| Automation Integration | High | Limited |

Clearly, for heavy-duty applications, the AC contactor is superior, ensuring reliability and safety over extended operational periods.

Applications of AC Contactors

AC contactors from Zhejiang Geyue Electric Technology Co., Ltd. are widely used in:

-

Motor control circuits

-

HVAC systems

-

Industrial lighting systems

-

Heating equipment

-

Automation panels

Choosing the Right AC Contactor

Selecting the proper AC contactor requires attention to:

-

Rated Current: Ensure it matches or exceeds the load current.

-

Coil Voltage: Select AC or DC coil according to control system requirements.

-

Durability: Consider mechanical and electrical lifespan for frequent operations.

-

Auxiliary Contacts: Check for additional signaling or interlocking needs.

Conclusion

An AC Contactor is a critical component in modern electrical systems, combining safety, automation, and reliability. Zhejiang Geyue Electric Technology Co., Ltd. provides a range of high-performance AC contactors tailored to industrial, commercial, and residential applications. For customized solutions, competitive pricing, and expert technical support, contact us today to explore how our AC contactors can optimize your electrical systems.