What Makes Large Scale Solar Energy Projects Truly Effective

2025-10-21

Hello, I’m a senior member of the team at TOPFence, and today I’d like to walk you through how we approach large-scale solar energy projects (especially solar farms) from a professional, experience-driven perspective. When you’re planning or investing in a solar farm, you’re looking at complex variables, long-term returns and operational realities. My goal here is to unpack those – help you avoid common pitfalls, understand our product parameters in detail, and see how TOPFence delivers strong value in this domain.

What Are the Key Challenges of Large Scale Solar Projects

When we embark on a large-scale solar project, the first question is always: what are the biggest pain points for our clients? In my twenty years with this industry I have seen some recurring themes:

-

Land and site suitability (size, orientation, shading, soil conditions)

-

Regulatory, permitting and grid-connection issues

-

Initial capital cost vs. long-term yield / ROI balance

-

Operational & maintenance (O&M) complexity — scale amplifies risks

-

Financing risk, especially for large-scale infrastructure

-

Supply chain reliability (panels, inverters, mounting systems)

For example, recent analysis shows that to reach net-zero goals in the U.S., a large number of utility-scale solar installations must be deployed weekly, which underscores the logistic and planning burden.

By addressing these pain points directly, at TOPFence we frame our product offering and service model in a way that helps clients with scale, reliability and lifecycle performance.

How Do We Define Our Product Parameters for a Solar Farm

Let me share the professional-level specs we use at TOPFence for our large-scale solar projects. I’ll present both a list and a table so you can clearly compare.

Key Product Parameter List

-

Module type: Mono-crystalline high-efficiency PV panels, typical efficiency 20 %+

-

Inverter strategy: Central inverters or string inverters (depending on site scale)

-

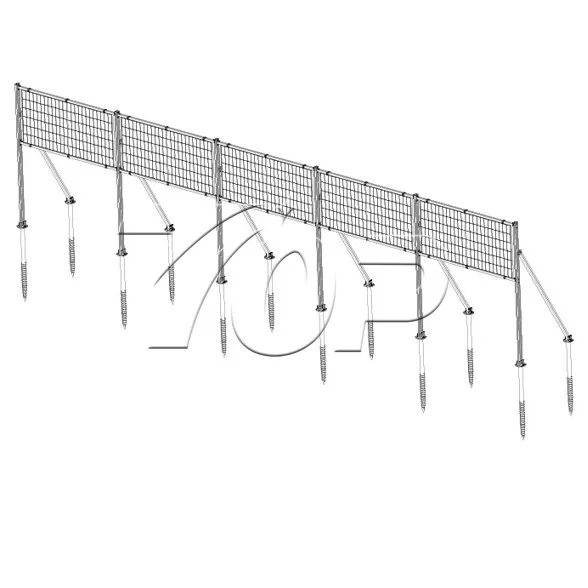

Mounting system: Fixed-tilt or single-axis tracking (depending on cost/yield trade-off)

-

Site layout: Optimised row spacing, tilt angle, shading analysis

-

Monitoring & SCADA: Real-time performance monitoring, fault detection

-

O&M plan: Preventive maintenance schedule, cleaning regime, component replacement plan

-

Warranty & performance guarantee: Panel degradation <0.5 %/yr, availability >98 %

Parameter Table for Typical TOPFence Solar Farm Package

| Parameter | Specification | Notes |

|---|---|---|

| Panel efficiency | ≥ 20 % | High-efficiency mono-crystalline |

| System size | From 10 MW up to 200 MW+ | Modular scaling approach |

| Mounting type | Fixed tilt or single-axis tracking | Tracking gives ~8-15 % higher yield |

| Inverter efficiency | ≥ 98 % | High-quality equipment reduces losses |

| Degradation rate (panels) | ≤ 0.5 %/year | Ensures long‐term yield stability |

| Availability (system uptime) | ≥ 98 % | Minimises downtime losses |

| Monitoring & fault detection | Real-time SCADA, remote diagnostics | Faster issue resolution |

| Expected annual yield | ~1,200 – 1,500 kWh per kW installed | Depends on site irradiance, tilt, tracking |

These parameters demonstrate how we at TOPFence structure our offering for large-scale solar energy projects. The use of high-efficiency panels, robust inverters, advanced monitoring and a solid O&M plan all help mitigate the major risks clients face.

Why Should You Choose a Full-Service Partner for a Solar Farm

Another key question I often get is: why not just assemble the parts yourself? Here’s why working with a partner like TOPFence makes sense for large-scale projects:

-

We manage end-to-end: from site assessment, design, procurement, construction to commissioning and O&M.

-

We provide a single point of accountability, which simplifies communication and reduces risk.

-

We leverage economies of scale: buying large volumes of panels/inverters/mounting gives cost advantages we pass on.

-

We apply proven project management practices honed over many large installations — fewer schedule delays, cost overruns.

-

We embed lifecycle performance oversight: it’s not just about initial build-out, but sustaining performance over 20+ years.

-

We stay current on regulatory/tax-incentive developments, grid-connection standards and market trends (which many clients find hard to follow on their own).

In short: by engaging us, you avoid many of the common pitfalls (cost blow-ups, yield shortfalls, operational headaches) and you gain a partner focused on your long-term return.

How Does TOPFence Handle Key Technical Areas for Solar Farms

Let’s drill down a little deeper into specific technical areas and how we address them:

Module selection & performance

We select modules with proven performance records, low degradation (≤0.5 % per year), good warranty terms (25 years for product, 30+ years for performance) and we perform detailed yield modelling based on your site’s irradiation, temperature, soiling risk and shading.

System layout & design optimisation

We perform detailed site modelling: tilt angles, row-spacing, shading analysis, string-layout optimisation, inverter loading strategies. We choose between fixed‐tilt vs. tracking depending on your budget/yield trade-off.

Inverter and electrical system

High‐quality inverters (efficiency ≥98 %) minimise losses. We design AC/DC cable routing, switchgear, transformer station, grid‐connection point. We ensure compliance with grid-code, reactive power management, harmonics.

Monitoring, SCADA and O&M strategy

We deploy a SCADA system that gives you real-time visibility of performance, alarms for faults, remote diagnostic capability. Our preventive maintenance schedule covers panel cleaning, inspection of mounting & modules, inverter servicing, vegetation management, etc. We aim for system availability ≥98 %.

Financial modelling & lifecycle analysis

We deliver an upfront financial model: CAPEX, OPEX, yield projections, degradation, payback period, IRR. We monitor performance annually and adjust operational plans so your real-world ROI tracks expectations.

What Does Our Typical Large Scale Solar Farm Project Look Like for You

Here’s a summary snapshot of a typical turnkey solar farm project we deliver:

-

Site: ~50 MW, mono-crystalline modules, fixed-tilt mounting.

-

CAPEX: Realistic budget, we deliver to agreed cost per MW.

-

Yield: ~1,350 kWh per kW installed per year (dependent on site).

-

Lifetime: 25-30 years design horizon, panel warranty 25 years, performance guarantee 80 %+ at year 25.

-

O&M plan: 20-year contract optional, includes preventive and corrective maintenance, remote monitoring, spare parts strategy.

-

Payback: Typically 6-9 years depending on incentives, tariff structure, financing.

How Can You Get Started With Us on a Solar Farm Project

If you are considering a large-scale solar energy project and want a partner who can handle everything from design to O&M, here’s the process we follow:

-

Initial consultation – We review your site, budget, objectives, timeline.

-

Feasibility study – We perform irradiation/tilt/row-spacing analysis, yield modelling, cost estimate.

-

Proposal & contract – We present our turnkey offering with full specs, deliverables, timeline.

-

Engineering & procurement – We design electrical system, lay-out, select components, plan logistics.

-

Construction & commissioning – We manage installation, testing, grid-connection, hand-over.

-

O&M & performance management – Post-commissioning we monitor performance, execute maintenance, provide reporting.

If you’re ready to explore how your large scale solar project can be realised with confidence and performance, let’s talk. Contact us today and we’ll schedule a detailed conversation about your site, objectives and how TOPFence can help turn your vision into reality.

Thank you for reading, and I look forward to working with you!