What Makes Winding Machine Accessories the Key to High-Precision and Efficient Coil Production?

2025-11-07

Winding machine accessories are precision-engineered components designed to support, enhance, and optimize the coil winding process across a wide range of industrial applications. These accessories are indispensable for sectors such as electrical, electronics, telecommunications, and motor manufacturing—where coils, transformers, and inductors demand consistent accuracy, efficiency, and uniform tension control.

In the context of today’s automation-driven production lines, winding machine accessories play a vital role in maintaining the reliability and performance of the winding process. They not only improve the quality of the final product but also significantly extend machine lifespan, reduce maintenance costs, and increase production speed.

A typical winding machine setup relies on several key accessories that work in harmony to achieve stable performance. Below is an overview of essential components commonly integrated into advanced winding systems:

| Component | Function | Material/Specification |

|---|---|---|

| Tension Controller | Maintains consistent wire tension to ensure precise winding | Electronic control; adjustable tension levels |

| Wire Guide Nozzle | Directs the wire accurately onto the bobbin or core | Stainless steel or ceramic material |

| Traverse Unit | Enables even distribution of wire across the coil width | Servo or mechanical-driven precision system |

| Bobbin Holder | Secures the coil core or bobbin during winding | Aluminum or carbon steel, adjustable clamping |

| Pay-off Stand | Feeds wire smoothly from spools without tangling | Motorized or friction type with torque control |

| Winding Die | Defines the wire path and shape for tight coil formation | Hardened steel or carbide construction |

| Counter System | Tracks turns and controls winding parameters | Digital encoder with display interface |

| Wire Break Detector | Instantly detects wire breakage or tension loss | Optical or mechanical sensor system |

| Automatic Cutter | Cuts wire cleanly after winding completion | Pneumatic or servo blade mechanism |

These components collectively determine the performance, precision, and durability of a winding machine. As production demands become more complex, integrating high-quality accessories becomes a strategic investment for manufacturers seeking competitive advantage and consistent quality output.

Why Are High-Quality Winding Machine Accessories Important for Production Efficiency?

The quality and precision of winding machine accessories directly influence the overall productivity and consistency of coil manufacturing. In industries where even a minor deviation in wire tension or alignment can cause electrical instability, premium accessories ensure smooth, error-free performance.

1. Enhanced Precision and Consistency

High-quality accessories such as digital tension controllers and servo-driven traverse units help maintain uniform coil winding. This precision guarantees consistent electrical characteristics, minimizing rejection rates and improving the reliability of the final product.

2. Increased Equipment Longevity

Durable materials like stainless steel, carbide, and aluminum ensure that components withstand high-speed operation and continuous wear. This extends machine life while reducing downtime caused by frequent part replacements.

3. Reduced Production Time

Modern winding accessories are designed for automation compatibility. Features like automatic wire cutting, tension feedback systems, and programmable counters reduce manual intervention and optimize cycle times.

4. Improved Safety and Stability

Advanced sensor systems detect wire breaks or tension loss instantly, preventing damage to coils or spools. This ensures operational safety and minimizes production waste.

5. Lower Maintenance Costs

Premium accessories require less frequent calibration and adjustment, minimizing the need for technical intervention. This cost efficiency is vital for manufacturers seeking to maintain large-scale production lines.

As the winding industry evolves, manufacturers are increasingly focusing on sustainable and intelligent solutions. Accessories are being upgraded with smart control systems, data collection capabilities, and integration with Industry 4.0 technologies. These innovations enable real-time monitoring and predictive maintenance, leading to a new era of precision-driven manufacturing.

How Are Winding Machine Accessories Evolving Toward Automation and Smart Manufacturing?

The future of winding machine accessories lies in intelligent automation, digital monitoring, and eco-friendly manufacturing practices. Modern production facilities are no longer limited to mechanical efficiency; instead, they aim for complete system optimization through smart integration.

1. Digital Control Systems

Future-ready accessories are increasingly adopting programmable logic controllers (PLCs) and servo systems. These provide adaptive control of winding speed, wire tension, and traverse accuracy, ensuring zero deviation across production batches.

2. Smart Sensors and IoT Integration

With the rise of Industry 4.0, accessories now include built-in sensors that monitor parameters such as wire tension, spool speed, and environmental temperature. This data can be transmitted to a centralized control system, allowing predictive maintenance and real-time optimization.

3. Sustainable Manufacturing Materials

Manufacturers are also turning to recyclable and long-lasting materials to minimize waste. Ceramic wire guides, for example, provide extended lifespan while maintaining low friction and heat generation, making them environmentally friendly and energy-efficient.

4. Customization and Modular Design

The future trend points toward modular accessory systems that can be easily adjusted or replaced based on production requirements. This flexibility enables faster changeovers, increased production versatility, and reduced downtime.

5. Integration with AI-Based Analytics and Robotics

While the mechanical aspect of winding remains essential, software-driven precision is redefining the way accessories function. Robotic arms for automatic bobbin replacement and smart counters for digital tracking are now common features in modern coil production facilities.

These technological advancements underline a global shift toward high-efficiency, data-driven manufacturing. As automation continues to dominate the industrial landscape, the demand for innovative winding machine accessories will keep rising, enabling higher production quality and output stability across industries.

Frequently Asked Questions (FAQs) About Winding Machine Accessories

Q1: What should be considered when selecting winding machine accessories for a new production line?

When selecting accessories, factors such as wire type, coil dimensions, required tension control, and production speed must be carefully evaluated. For high-speed operations, servo-driven traverse units and digital tension controllers are essential. Additionally, the compatibility of accessories with the machine’s control system should be verified to ensure seamless synchronization. Materials like ceramic or stainless steel are recommended for durability and low friction.

Q2: How can regular maintenance of winding machine accessories improve production quality?

Regular maintenance ensures the stability of key parameters such as wire tension, alignment, and winding speed. Cleaning the wire guide nozzles, checking the traverse mechanism for debris, and calibrating the tension controllers periodically prevent uneven winding and wire breakage. Preventive maintenance also reduces downtime, enhances precision, and extends the life of both the accessories and the machine itself.

The Future Direction and Industrial Significance of Winding Machine Accessories

The global manufacturing sector is entering an era of smart automation, and winding machine accessories are at the core of this transformation. As industries demand higher efficiency, consistency, and adaptability, manufacturers are investing in accessories that support advanced control systems and digital feedback technologies.

The next generation of winding accessories will feature more compact designs, real-time monitoring capabilities, and energy-saving mechanisms. By leveraging sensor-based diagnostics and automated adjustment systems, these accessories will enable machines to self-optimize during production—eliminating human error and improving yield rates.

In the broader industrial context, the importance of winding machine accessories extends beyond mechanical performance. They represent a commitment to innovation, quality assurance, and environmental responsibility. Manufacturers that adopt state-of-the-art accessories gain measurable advantages in competitiveness, operational reliability, and long-term cost reduction.

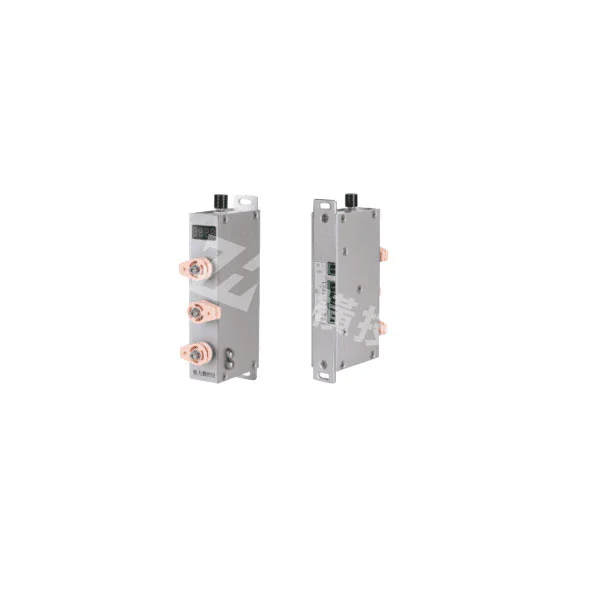

The Role of Zongheng in Advancing Winding Machine Technology

As a professional manufacturer committed to precision engineering, Zongheng continuously invests in developing durable, high-performance winding machine accessories tailored for diverse industrial needs. With a strong focus on quality, innovation, and efficiency, Zongheng’s accessories are designed to meet the evolving requirements of modern automated production.

From precision tension control to smart sensor integration, Zongheng ensures that every accessory contributes to smoother operations, longer machine life, and superior coil quality.

For more details about Zongheng’s comprehensive range of Winding Machine Accessories, or to discuss customized solutions for your production needs, Contact Us today to discover how our products can enhance your manufacturing efficiency and reliability.