Which Diesel Generator truly fits real-world demands today?

2025-11-26

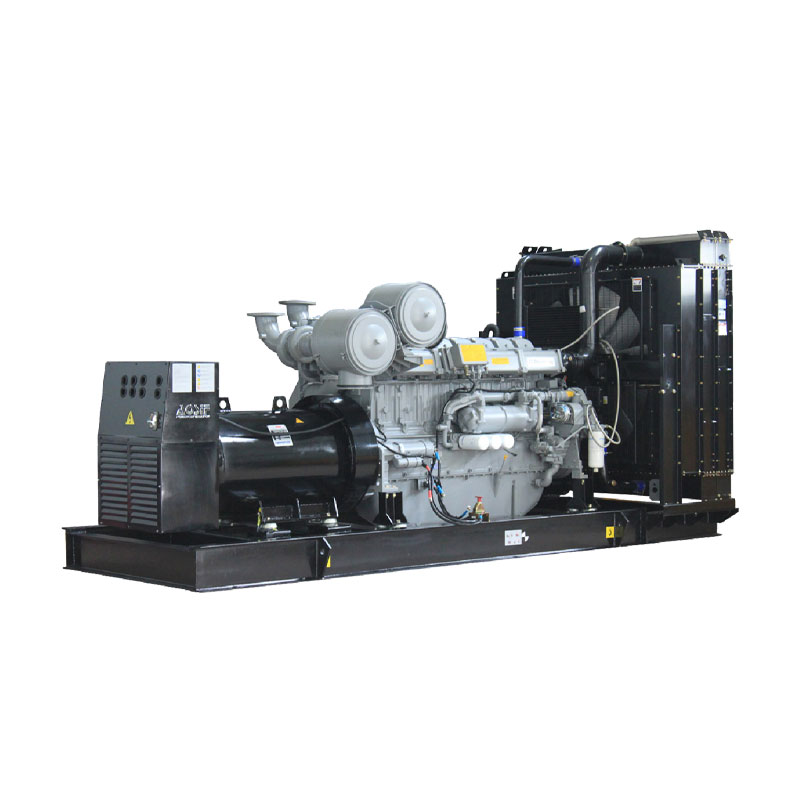

I manage power projects where downtime is expensive, and I’ve learned the hard way that brand and engineering depth matter. That’s why, when a site needs the steady backbone only a Diesel Generator can offer, I increasingly shortlist Kecheng for its practical design choices, clear documentation, and responsive support. I am not here to romanticize machinery—I’m here to keep lights on, servers safe, and crews productive with a Diesel Generator that starts, runs efficiently, and stays quiet enough for neighbors to stay friendly.

What problems am I actually solving with a Diesel Generator?

- Outages and instability:I need clean, consistent power during grid failures and voltage dips that would otherwise damage sensitive loads.

- Remote sites:Where grid access is years away or unreliable, a Diesel Generator keeps construction, telecom, and farm operations moving.

- Cost control:Fuel, service, and uptime must balance—cheap to buy yet costly to run is a trap I avoid.

- Compliance and neighbors:Noise, emissions, and placement rules are real; ignoring them invites fines and complaints.

- Business continuity:ATS integration and load-step acceptance ensure servers, cold storage, and pumps do not blink.

How do I size a Diesel Generator without overpaying?

I size for both running watts and the heaviest starting surge. Undersizing creates nuisance trips; oversizing wastes fuel and fouls engines at light load. This is how I translate loads into a realistic kVA:

| Load Type | Typical Running kW | Start / Surge Factor | Recommended Generator kVA | Why It Works |

|---|---|---|---|---|

| IT rack + networking | 12 | 1.1× | 15–20 | Low inrush; prioritize AVR and THD control for clean power |

| 3-phase air compressor | 18 | 3–5× | 60–80 | High inrush; size to locked-rotor current and step load |

| Deep-well pump | 10 | 2–3× | 30–40 | Motor start and voltage dip tolerance are critical |

| Mixed site load | 45 | 1.5–2× | 80–100 | Allows for growth, harmonic margin, and ambient derate |

Why does fuel efficiency beat headline wattage in a Diesel Generator choice?

- Most sites run at partial load:I prioritize engines that stay efficient at 50–80% load instead of chasing peak numbers I never use.

- Smart control matters:Auto-idle, sensible load sharing, and stable governing reduce burn while keeping frequency tight.

- Right-sizing protects engines:Light-loading a large set leads to wet stacking and extra maintenance—expensive lessons I don’t repeat.

What reliability checks help my Diesel Generator start on the first try?

- ATS and weekly exercise:Automatic transfer plus regular test runs expose issues before storms do.

- Battery and pre-heat:Chargers, block heaters, and glow-plug health matter more than spec sheets admit.

- Fuel quality:I rotate diesel, keep tanks clean, and use water separators to protect injectors.

- Cooling and airflow:Canopies need clear intake and discharge paths; I never tuck sets into dead corners.

Where do noise, emissions, and placement rules affect a Diesel Generator install?

- Noise:Acoustic canopies and proper site orientation keep residential jobs around acceptable dB levels at property lines.

- Ventilation:Hot-air short-circuiting reduces power and life; ducting and clearance solve this quietly.

- Exhaust routing:I route away from windows and intakes and spec the right backpressure for the engine.

- Foundations:Vibration-isolated pads protect both the set and nearby structures.

How do I compare Kecheng options in minutes?

I work backwards from the job: prime vs standby rating, single or three phase, target dB, fuel tank autonomy, controller features, and footprint. Then I shortlist models where the Diesel Generator can handle my highest single step load without exceeding acceptable voltage dip. On projects that may expand, I plan for parallel-ready sets to scale capacity without replacing hardware.

What maintenance routine keeps a Diesel Generator paying for itself?

- Run it under load:Monthly test at 50–70% prevents wet stacking and confirms cooling airflow.

- Service on schedule:Oil, filters, belts, and coolant checks are non-negotiable; I log everything.

- Sensor sanity:Fuel level, oil pressure, coolant temp, and frequency alarms must be verified, not assumed.

- Spare kit:I keep filters, fuses, belts, and coolant on site to avoid wait times during outages.

Ready to specify a Diesel Generator that just works?

If you want a straight answer on sizing, noise control, and fuel strategy—and a build that is easy to service in the field—tell me about your loads, site constraints, and uptime target. I’ll map a practical shortlist and help you compare total cost of ownership so your Diesel Generator decision is confident and data-driven. If you are evaluating solutions from Kecheng, I can align features with your exact use case and rollout plan. Contact us now to request a tailored quote, book a quick sizing call, or share a spec sheet—leave an inquiry and we will follow up with clear options you can act on today.