Why Choose an Isolation Switch for Reliable Electrical Safety?

2025-09-12

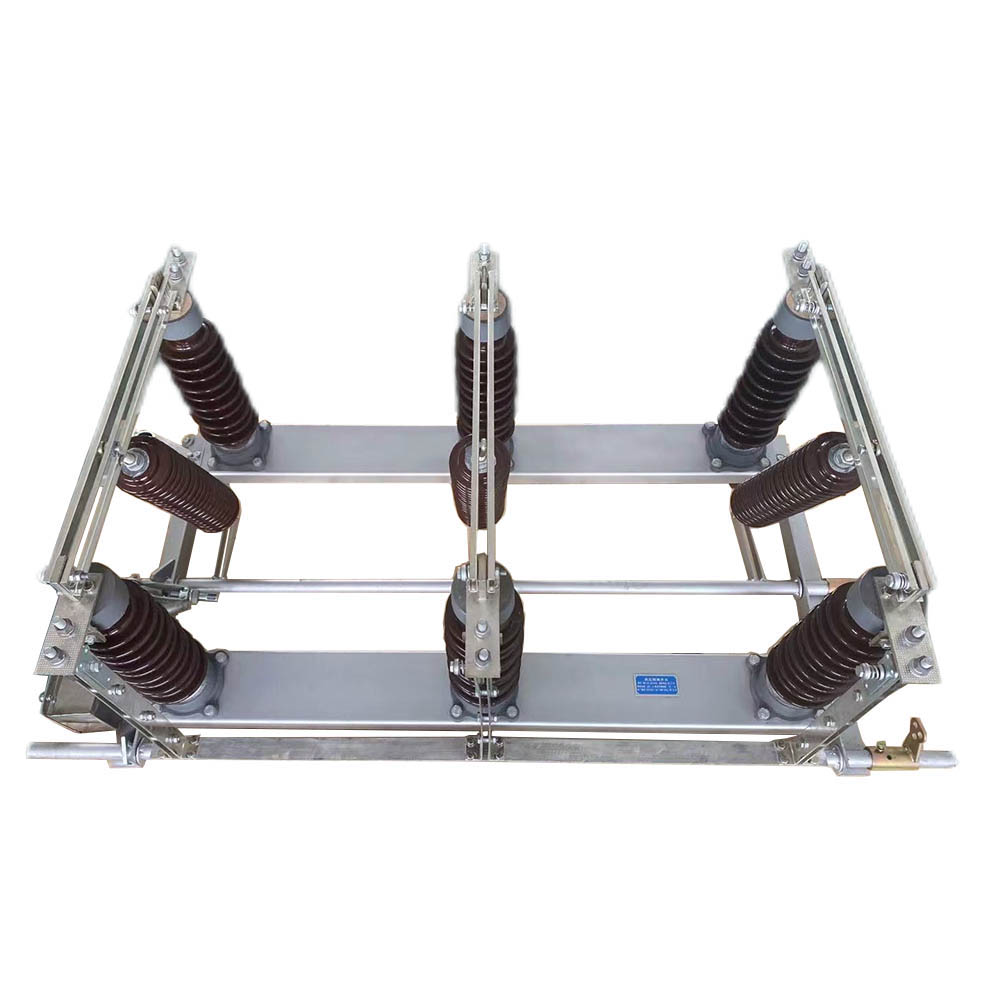

Electricity powers modern life, from residential spaces to industrial complexes. But with the benefits of electrical power come risks—especially if circuits and equipment are not safely managed. An Isolation Switch, often called an isolator or disconnector, is an essential device designed to provide safety, efficiency, and reliability by fully cutting off power to specific circuits or equipment when maintenance, testing, or repair is needed.

So, why is this important? Unlike a circuit breaker, which automatically interrupts current in case of overload, an Isolation Switch serves a deliberate, manual function. It ensures that an electrical circuit is completely de-energized, preventing unexpected currents from flowing while engineers or technicians work on the system. This level of safety control reduces the risk of electric shocks, fire hazards, and costly downtime.

The primary role of an Isolation Switch includes:

-

Disconnecting a power source from the circuit for maintenance.

-

Providing a visible and verifiable break in the electrical supply.

-

Ensuring compliance with international safety standards.

-

Supporting smooth operations in residential, commercial, and industrial electrical systems.

Without isolation switches, maintenance crews would risk handling live wires unknowingly, exposing themselves to severe electrical hazards. That’s why in many regulated markets, isolation switches are mandatory in certain installations, from solar photovoltaic systems to heavy industrial equipment.

Furthermore, the demand for reliable isolation switches is increasing globally. With the rise of renewable energy systems, smart grids, and high-capacity electrical installations, the importance of having safe, certified, and efficient disconnecting devices cannot be overstated.

How an Isolation Switch Works and the Key Features to Look For

An Isolation Switch works on a simple yet critical principle: it creates a clear gap between the power source and the load. When switched off, the device physically separates electrical contacts, ensuring that no current flows to downstream equipment. This physical separation guarantees that even accidental energization cannot occur, which is why isolation switches are trusted in high-risk environments.

Mechanism in Action

-

Open Position (Isolated): The switch handle is moved to the “off” position, opening the contacts and creating a visible gap. The circuit is now completely de-energized.

-

Closed Position (Operational): The contacts close firmly, allowing current to flow safely through the circuit.

This mechanism can be manual, semi-automatic, or motor-operated, depending on the application.

Key Features of a Quality Isolation Switch

When selecting an isolation switch, it is important to consider:

-

Voltage and Current Rating: Compatibility with your system’s requirements, e.g., 240V or 415V with current ratings from 16A to 1250A.

-

Number of Poles: Single-pole, double-pole, triple-pole, or four-pole configurations depending on single-phase or three-phase systems.

-

Mounting Type: Options include panel-mounted, DIN rail-mounted, or wall-mounted switches.

-

Switching Speed: Quick-action designs enhance user safety and reduce arc generation.

-

Durability: High mechanical life and resistance to wear, especially for frequent switching operations.

-

Compliance: IEC, UL, or other relevant certifications for global use.

Example Product Parameters (Richge Isolation Switch Series)

| Parameter | Specification Options |

|---|---|

| Voltage Rating | 240V AC / 415V AC |

| Current Rating | 16A, 32A, 63A, 125A, 250A, 400A, up to 1250A |

| Poles | 1P, 2P, 3P, 4P |

| Mounting Type | DIN Rail, Panel Mount, Wall Mount |

| Operation | Manual / Motorized |

| Standards Compliance | IEC 60947-3, CE, UL Certification |

| Mechanical Endurance | 10,000+ operations |

| Application Areas | Residential, Commercial, Industrial, Renewable Energy |

These parameters ensure that the switch can meet the needs of small residential projects, large-scale manufacturing plants, and renewable installations such as solar farms.

Isolation switches are not one-size-fits-all. Choosing the right product requires understanding your power system, current flow, and safety requirements. High-quality switches also integrate arc suppression systems, making them suitable for demanding industrial environments where high loads are common.

Where Isolation Switches Are Used and Why They Are Indispensable

Isolation switches have a wide range of applications across multiple sectors, ensuring electrical safety and operational efficiency. Their universal presence in modern systems is a testament to their importance.

Residential Applications

-

Main Power Control: Homeowners use isolation switches to disconnect supply to entire households during renovations or repairs.

-

Air Conditioning Units: Dedicated isolators ensure that maintenance can be done without exposing technicians to live circuits.

-

Solar PV Systems: Solar inverters require isolators on both AC and DC sides for safety and regulatory compliance.

Commercial Applications

-

Retail and Office Buildings: Isolation switches help facilities managers isolate lighting, HVAC, and elevator systems during routine maintenance.

-

Data Centers: To protect servers and critical infrastructure, isolation switches allow precise control of power distribution.

Industrial Applications

-

Manufacturing Plants: Heavy-duty isolation switches cut power to machinery before servicing, minimizing downtime and accidents.

-

Mining Operations: Harsh environments demand rugged, dust-proof, and waterproof isolators.

-

Oil & Gas Facilities: Explosion-proof isolation switches are installed in hazardous zones to guarantee safety.

Renewable Energy Systems

-

Solar Power Farms: Multiple isolation switches manage connections between panels, inverters, and grid connections.

-

Wind Turbines: Installed for system disconnection during inspection or technical issues.

Why They Are Indispensable

-

Safety Assurance: A visible break in the circuit ensures no accidental power flow.

-

Regulatory Compliance: Many countries require isolation switches by law for specific electrical systems.

-

Maintenance Flexibility: Technicians can confidently service equipment without interrupting the entire grid.

-

Operational Reliability: Protects sensitive equipment by controlling when and how electricity flows.

As industries embrace automation, renewable energy, and high-capacity networks, isolation switches have become central to safe electrical infrastructure. Their reliability prevents accidents, increases operational uptime, and safeguards assets worth millions.

Future Trends, FAQs, and Why Richge is Your Trusted Partner

Future of Isolation Switches

With the global shift toward renewable energy and smart grids, isolation switches are evolving:

-

Smart Isolation Switches: Integrated with IoT systems for remote monitoring and predictive maintenance.

-

Eco-Friendly Materials: Manufacturers are adopting recyclable and low-impact materials.

-

Compact Designs: Space-saving isolators are increasingly in demand for residential and commercial projects.

-

Advanced Arc Protection: New designs further reduce arc hazards in high-load industrial environments.

The market for isolation switches is expected to expand significantly as countries push for safer, greener, and more efficient electrical infrastructure.

Common Questions About Isolation Switches

Q1: What is the difference between an isolation switch and a circuit breaker?

A circuit breaker is designed to interrupt current automatically in case of overload or short circuit, protecting equipment from damage. An isolation switch, however, is used to manually disconnect the circuit completely for safety during maintenance or repairs. While both are safety devices, they serve different but complementary purposes.

Q2: How do I know which isolation switch is suitable for my application?

Selection depends on several factors: voltage and current ratings, number of poles, installation environment, and compliance with local regulations. For instance, a residential solar PV system might require a 2P DC isolator, while an industrial factory may need a 4P, 400A isolator. Consulting technical datasheets and verifying certification compliance ensures you choose the right product.

Why Choose Richge Isolation Switches?

Isolation switches are not just optional accessories—they are fundamental components of any safe electrical system. From residential households to industrial plants and renewable energy projects, they ensure that circuits can be completely de-energized, protecting people, equipment, and property. With growing demand for safer and smarter electrical solutions, the role of high-quality isolation switches will only become more critical.

Richge delivers a full range of isolation switches engineered for performance, safety, and durability. With compliance to international standards and a focus on innovation, Richge products provide peace of mind for contractors, electricians, and end-users alike.

If you are planning a project or need reliable solutions for electrical safety, contact us today to explore our complete range of isolation switches tailored to your specific needs.