Why do I trust an Automatic Transfer Switch to keep my power plans honest?

2025-12-10

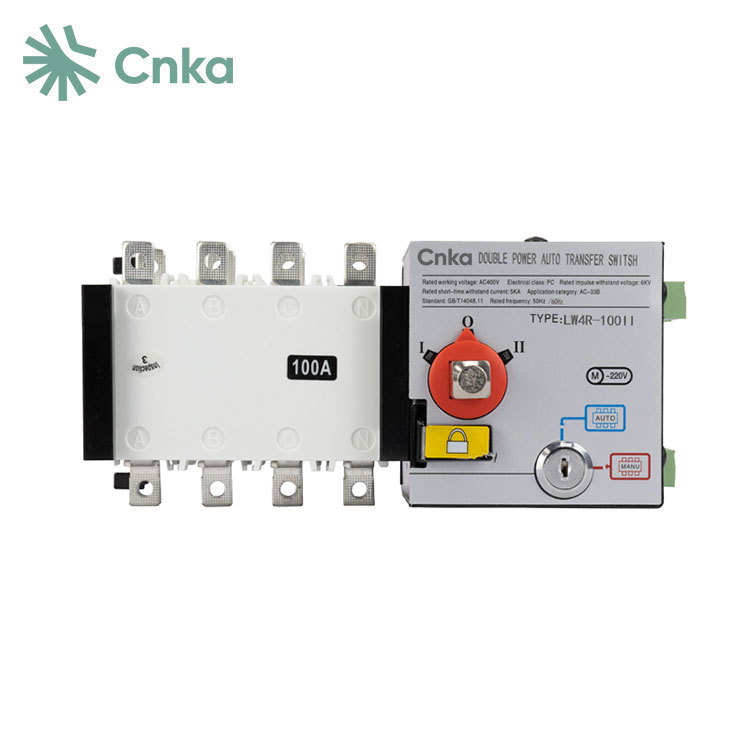

I learned early that outages don’t negotiate, and neither should the hardware that guards my revenue. On projects from small clinics to light manufacturing, the quiet hero has been the Automatic Transfer Switch. As my sites grew more complex—utility plus generator, or utility plus PV inverter—I kept circling back to gear that simply works. That is where brands like CNKA came into my orbit: not as a loud logo, but as dependable switchgear that fit my checklists without fuss.

Do I really need an Automatic Transfer Switch when a manual switch seems cheaper?

When I run the math on downtime, the “cheap” option ages fast. A proper Automatic Transfer Switch removes hesitation in the two moments that matter most—when the utility fails and when it returns. I’ve seen it protect refrigeration stock, EMR servers, and CNC cycles because it acts in seconds without waiting for a human who might be off-site. If your loads are mission-critical for safety, compliance, or perishable goods, automation isn’t luxury—it’s the floor.

- Safety: mechanical and electrical interlocks prevent backfeed into a dead or unsafe source.

- Speed: configurable delays keep transfer clean—no frantic rushing to a panel at 2 a.m.

- Consistency: the same logic every time, not “whoever was on duty.”

- Compliance: easier to meet inspector expectations when the interlocks and labeling are baked in.

What makes an Automatic Transfer Switch reliable in real outages?

I look past buzzwords to measurable items. Contacts should have documented making and withstand ratings. The logic should support open-transition as a default and optional closed-transition where the power ecosystem allows it. Four-pole designs that switch the neutral help with certain generator and inverter topologies. Thermal performance matters too: I check temperature rise at rated current and cycle life of the mechanism.

- Interlock strategy: true break-before-make unless your system is engineered for momentary overlap.

- Programmable delays: transfer, retransfer, generator warm-up, and cooldown timers.

- Source priority: choose which source is “preferred” and when to return to it.

- Health signals: dry contacts, LEDs, and remote alarms that talk to BMS or a small PLC.

- Environmental rating: the right enclosure (NEMA/IEC) for dust, moisture, or outdoor sun.

How do I size an Automatic Transfer Switch without playing it dangerously safe?

Oversizing can mask problems and inflate cost; undersizing leaves you exposed. I start from continuous current, account for starting inrush on motors, and confirm the short-circuit ratings against available fault current. Where harmonics from VFDs and inverters are high, I leave margin for heat. Then I map settings to operating reality; there’s no sense in a lightning-fast transfer if the generator needs 10–15 seconds of warm-up to stabilize frequency and voltage.

Here’s the planner I use to quickly match loads, sources, and settings before I specify an Automatic Transfer Switch.

| Scenario | Typical load | Source pair | Recommended ATS type | Core settings | Notes |

|---|---|---|---|---|---|

| Small clinic IT + HVAC | 60–150 A, mixed motor + electronics | Utility + generator | Open-transition, 4-pole if neutral switching is needed | Warm-up 10–15 s; transfer delay 2–5 s; retransfer 5–10 min | Avoid closed-transition unless sources can sync |

| Retail with freezers | 100–250 A, high inrush | Utility + generator | Open-transition, high withstand rating | Staggered restart via downstream breakers | Protect compressors: add time delays on branch circuits |

| Office with PV inverter backup | 80–200 A, sensitive electronics | Utility + inverter | Open-transition, 4-pole neutral | Short transfer delay; verify inverter ride-through | Confirm anti-islanding rules and labeling |

| Light manufacturing | 200–600 A, VFDs + motors | Utility + generator | Open-transition; consider bypass-isolation | Warm-up 15–20 s; retransfer when stable for 15 min | Bypass lets me service the ATS without shutdown |

Why do transfer time and neutral switching change the outcome?

Neutral handling is equally pivotal: with certain grounding schemes and sensitive electronics, a switched neutral prevents nuisance trips and odd currents. When I specify an Automatic Transfer Switch for mixed loads, four-pole often saves me headaches later.

- Open-transition: safest default—never ties sources together.

- Closed-transition: only where synchronization and utility rules allow it.

- Neutral policy: fixed vs switched—decide based on generator bonding and codes.

How do I install and test so the first outage feels uneventful?

My rule: I never call a project complete until I watch a live functional test. I verify labeling, torque on lugs, and clearances. Then I simulate a utility failure to confirm timing, alarms, and load behavior. I record baseline temperatures with a thermal camera after a few hours of load, so I have a reference for future maintenance.

- Witness the sequence: utility fail → start signal → generator stable → transfer → retransfer.

- Log settings: time stamps, voltages, frequencies, and delays.

- Train staff: one laminated one-pager beats a binder nobody reads.

- Schedule checkups: exercise the generator and cycle the switch monthly or quarterly.

Which mistakes cost me the most on ATS projects and how do I avoid them?

- Ignoring fault current: the ATS must withstand available short-circuit levels.

- Forgetting inrush: compressors and elevators spike—coordinate downstream delays.

- Wrong neutral choice: fixed vs switched changes nuisance trip risk.

- No bypass: maintenance becomes painful on 24/7 sites.

- Unclear source priority: decide if you retransfer to utility automatically or stay on backup until stable for a set window.

Where does CNKA fit when my footprint grows and my risks go up?

When I move from a small panelboard to a whole-facility approach, I want options without changing the playbook. That’s where CNKA-style modularity helps: current ranges that step up cleanly, enclosure choices that match the site, and accessory kits—metering, remote alarms, bypass-isolation—that I can add without redoing the room. If I’m standardizing, I prefer one family of Automatic Transfer Switch products across amperages so operations teams only learn one interface.

What questions do I ask vendors before I commit money?

- Can you show test data for contact temperature rise at rated current?

- What is the short-circuit withstand rating with my upstream protection?

- How many mechanical and electrical operations is the mechanism rated for?

- Can I get four-pole and bypass-isolation in the same family if I scale later?

- Which communications are available for alarms and BMS integration?

How do I phrase the spec so it’s clear I want an Automatic Transfer Switch that behaves predictably?

I write in outcomes first: no source overlap unless engineered, programmable delays for transfer and retransfer, neutral policy defined, minimum withstand to match fault current, enclosure to suit the environment, and documented test at commissioning. Then I let vendors propose models that meet or exceed, with one consistent logic platform across sizes. The result is a site that treats outages like routine events.

Ready to make outages boring and operations calm?

If you’re weighing generator size, inverter topology, or just trying to pick the right Automatic Transfer Switch for a mixed-load panel, I’m happy to help structure the decision. Tell me about your loads, your sources, and your uptime goals, and we’ll turn that into a clean, tested plan built around the right Automatic Transfer Switch. When you’re ready, contact us and share a one-line diagram or a simple load list—I’ll map it to a practical Automatic Transfer Switch configuration and timing profile. Power cuts happen; panic doesn’t have to.